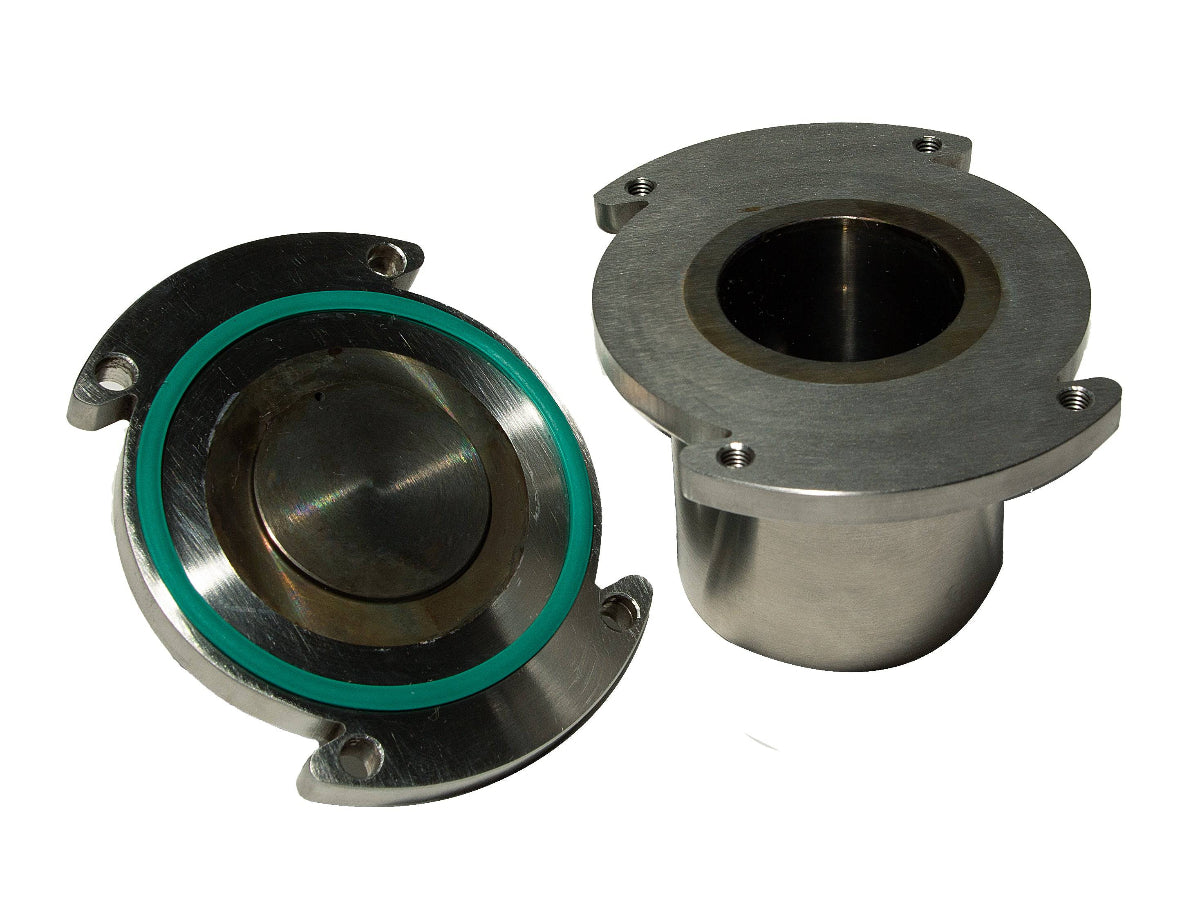

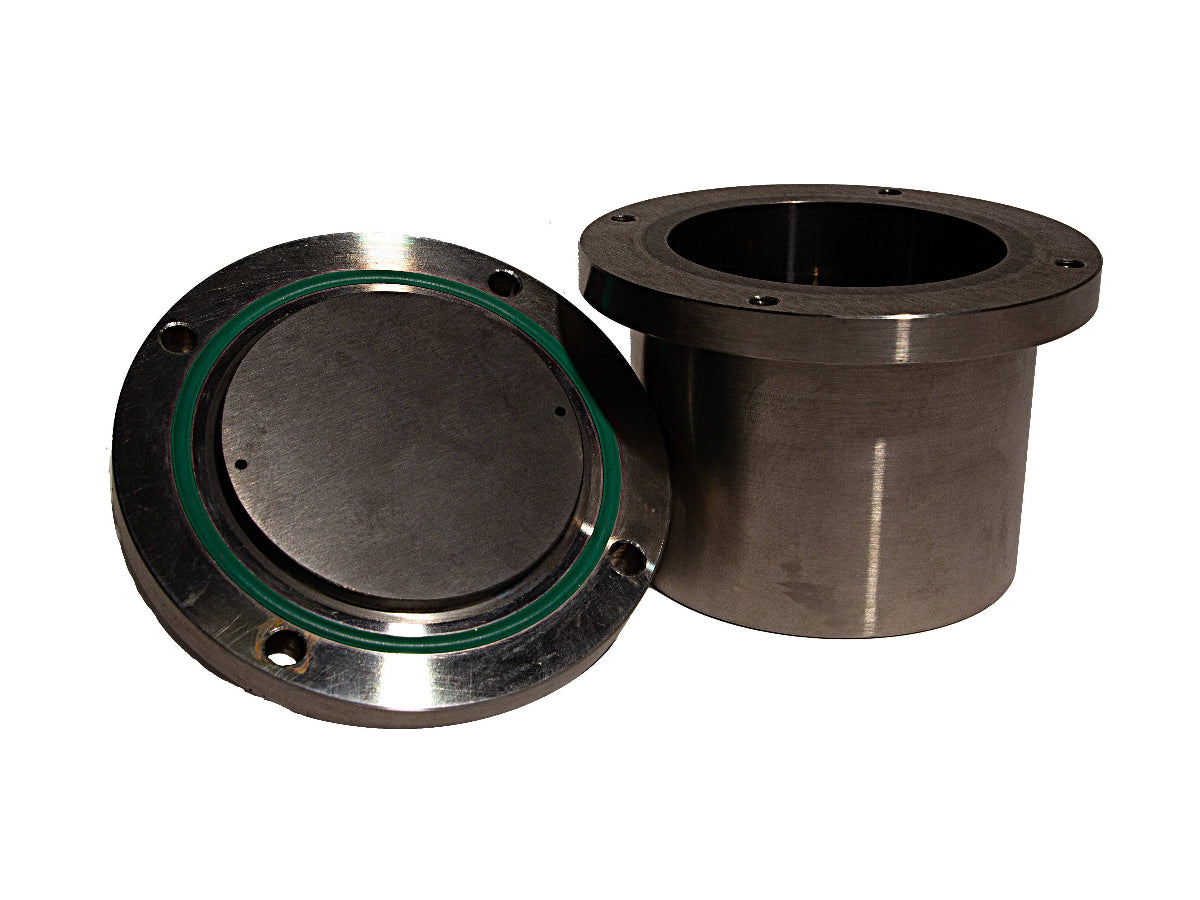

Cell Lab Tungsten Carbide (WC) Vacuum Planetary Milling Jars [50 ml, 250 ml, 500 ml, 1000 ml]

- £1,039.00

- £1,039.00

- Unit price

- / per

Description

xCell Lab Tungsten Carbide (WC) Vacuum Planetary Milling Jars [50 ml, 250 ml, 500 ml, 1000 ml]

High-density vacuum jars for oxidation-sensitive materials

The Cell Lab Tungsten Carbide (WC) Vacuum Planetary Milling Jars are engineered for high-performance grinding and mixing of hard, brittle, and oxidation-sensitive materials.

These specialised vacuum jars feature a 304 stainless steel outer jacket and silicone sealing system, allowing safe operation under vacuum or inert gas conditions to prevent oxidation and contamination.

Each jar is constructed from tungsten carbide reinforced with cobalt, delivering outstanding hardness, wear resistance, and mechanical strength.

Ideal for use in metallurgy, ceramics, chemical engineering, electronic materials, and battery research, these jars ensure consistent and reproducible fine powder production in demanding laboratory environments.

Key Features

-

Vacuum-compatible design – supports operation under vacuum or argon/nitrogen atmosphere to protect reactive or oxidation-sensitive samples.

-

Exceptional durability – tungsten carbide (WC–Co) construction encased in stainless steel ensures superior wear resistance and long service life.

-

High grinding efficiency – excellent for hard, dense, and brittle materials such as carbides, oxides, and metallic alloys.

-

Precision sealing system – stainless steel lid with silicone gasket provides airtight sealing and stable vacuum retention.

-

Broad scientific applicability – suitable for R&D in metallurgy, ceramics, chemicals, geology, and energy materials.

Technical Specifications

|

Specification |

CL0315 |

CL0316 |

CL0317 |

CL0318 |

|

Jar Volume |

50 ml |

250 ml |

500 ml |

1000 ml (1L) |

|

Compatible Planetary Mill |

0.4L or 1-4L |

≥ 2L |

4L |

8L |

|

Max Loading Capacity |

≤ 2/3 jar volume |

|||

|

Outer Diameter (mm) |

55 |

89 |

106 |

131 |

|

Inner Diameter (mm) |

38 |

73 |

– (vacuum sleeve ID not specified) |

115 |

|

Height (mm) |

65–67 (depending on mill type) |

84 |

111 (jar body, nozzle 40 mm) |

122 |

|

Density (g/cm³) |

14.95 |

|||

|

Main Composition |

WC (94%), Co (6%) |

|||

|

Hardness |

92.1 HRA |

|||

|

Shape |

Cylindrical |

|||

|

Attachments |

Lid + Silicone Sealing Gasket |

|||

|

Abrasion Resistance |

Very good |

|||

Applications & Industries

Cell Lab WC vacuum milling jars are ideal for:

-

Battery materials R&D – safe handling of oxygen-sensitive electrode powders under inert conditions.

-

Metallurgical and ceramic synthesis – high-density milling of oxides, nitrides, and carbides.

-

Electronic materials – grinding semiconductors, magnetic compounds, and conductive materials.

-

Chemical and geological analysis – pulverising hard minerals and chemical precursors.

-

Environmental and nanomaterials research – precise reduction of particle size in controlled environments.

FAQ

Q1: Why use tungsten carbide jars instead of stainless steel or zirconia?

A: WC jars offer much higher hardness and density, enabling faster grinding of hard or abrasive materials and minimising contamination from the jar walls.

Q2: Can these jars be used under vacuum or inert gas?

A: Yes. The stainless steel outer shell and silicone gasket allow operation under vacuum or argon/nitrogen atmosphere to prevent oxidation.

Q3: Are the jars compatible with all planetary mills?

A: They fit most standard planetary mills (0.4 L–8 L models). Compatibility depends on the jar clamp size and rotation radius.

Q4: What grinding media are recommended?

A: Use tungsten carbide balls for maximum efficiency and matched hardness; other media may cause contamination or uneven wear.

Q5: How should I maintain the vacuum seal?

A: Inspect and clean the gasket after each use, avoid solvent exposure to silicone, and ensure proper alignment during closure.

Shipping & Return

xReturns Policy

You may return most new, unopened items within 30 days of delivery for a full refund. We'll also pay the return shipping costs if the return is a result of our error (you received an incorrect or defective item, etc.).

You should expect to receive your refund within four weeks of giving your package to the return shipper, however, in many cases you will receive a refund more quickly. This time period includes the transit time for us to receive your return from the shipper (5 to 10 business days), the time it takes us to process your return once we receive it (3 to 5 business days), and the time it takes your bank to process our refund request (5 to 10 business days).

If you need to return an item, simply login to your account, view the order using the "Complete Orders" link under the My Account menu and click the Return Item(s) button. We'll notify you via e-mail of your refund once we've received and processed the returned item.

Shipping

We can ship to virtually any address in the world. Note that there are restrictions on some products, and some products cannot be shipped to international destinations.

When you place an order, we will estimate shipping and delivery dates for you based on the availability of your items and the shipping options you choose. Depending on the shipping provider you choose, shipping date estimates may appear on the shipping quotes page.

Please also note that the shipping rates for many items we sell are weight-based. The weight of any such item can be found on its detail page. To reflect the policies of the shipping companies we use, all weights will be rounded up to the next full pound.

- Choosing a selection results in a full page refresh.