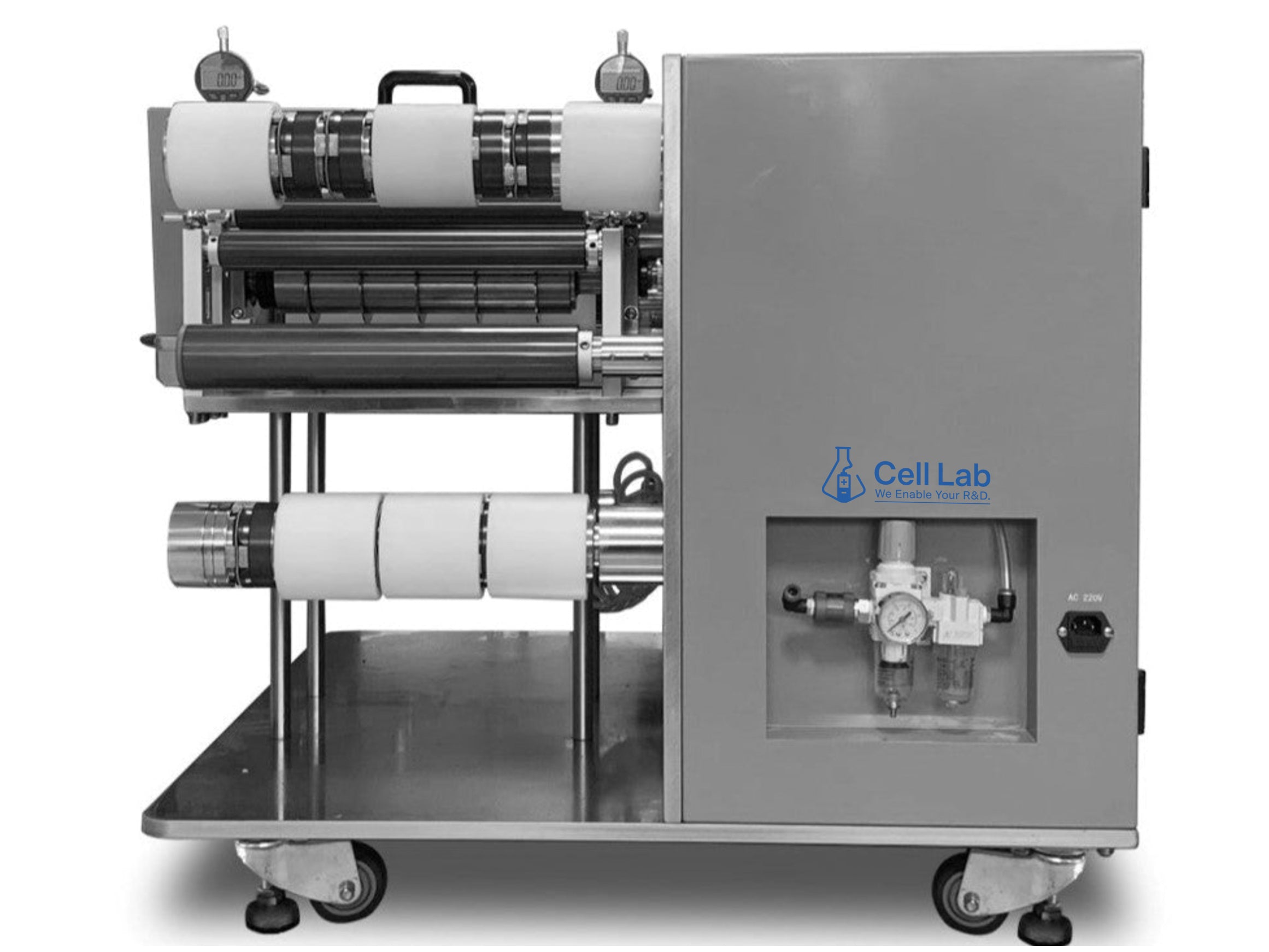

Cell Lab Roll-to-Roll Continuous Slitting Machine [For Battery Electrode Cutting | High-Precision Film Slitter]

- £32,900.00

£0.00- £32,900.00

- Unit price

- / per

Description

xCell Lab Roll-to-Roll Continuous Slitting Machine [For Battery Electrode Cutting | High-Precision Film Slitter]

High-accuracy roll-to-roll slitting solution for lithium battery electrode and functional film materials

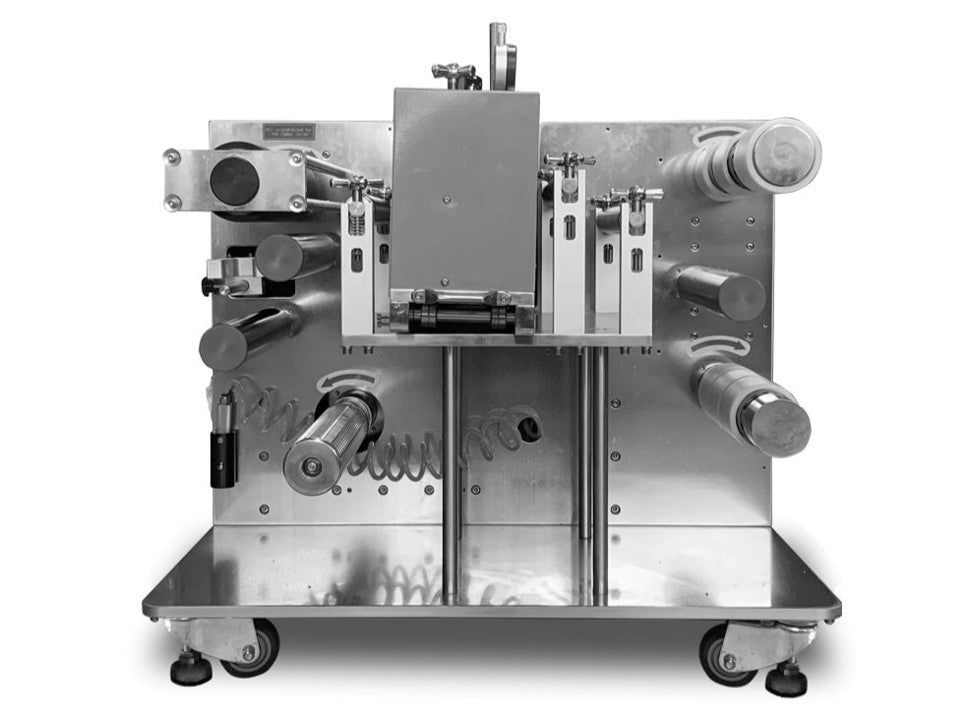

The Cell Lab Roll-to-Roll Continuous Slitting Machine is designed for precision cutting of lithium-ion battery electrodes and advanced functional films. Utilising ultra-fine alloy blades and PLC-controlled automation, this system ensures smooth, burr-free slitting with adjustable cutting widths and stable high-speed performance. Ideal for laboratory R&D and pilot-scale electrode production, it guarantees accuracy, repeatability, and clean operation.

Key Features

-

High-Precision Cutting: Ultra-fine alloy steel circular blades deliver smooth edges with minimal burrs and deformation.

-

Adjustable Slitting Width: Spacer-based system allows fine adjustment from 20–280 mm, with custom configurations available.

-

PLC-Controlled Automation: Integrated control system with touchscreen HMI provides intuitive setup, real-time speed and tension adjustments.

-

Clean and Stable Operation: Independent knife holder and dust removal system ensure safe, efficient, and debris-free performance.

-

Material Versatility: Suitable for slitting electrode sheets, separator films, and other flexible substrates with 100–300 μm thickness.

Technical Specifications:

| Specification | Details |

|---|---|

| Power Supply | 220V AC ±10%, 50/60Hz |

| Cutting Blade | Ultrafine alloy steel, Φ100mm |

| Cutter Type | Upper and lower circular blade |

| Material Thickness | 100–300μm |

| Slitting Method | Monolithic roll cutting |

| Slitting Width | 20–280mm (adjustable via spacers; customisable) |

| Slitting Speed | Max. 4m/min |

| Slitting Accuracy | ±0.09mm |

| Knife Feed Range | 0.2–0.4mm (with dial indicator display) |

| Burr Condition | ≤25μm |

| Operating Conditions | 25 ± 3°C, 30–90% RH, vibration- and EMI-free environment |

| Installation Size (L×W×H) | 850 × 800 × 650mm |

| Weight | ~550kg |

Note: Custom slitting configurations (width, blade type, speed, or film material) are available upon request.

Applications & Industries

-

Lithium-ion and solid-state battery electrode slitting

-

Precision cutting of copper, aluminium, and coated electrode foils

-

Separator and functional film roll processing

-

Laboratory and pilot-scale electrode production lines

-

Energy storage, flexible electronics, and coating R&D

FAQ

Q1: What materials can this machine slit?

It supports a wide range of materials including coated electrodes, copper foil, aluminium foil, and separator films.

Q2: How accurate is the slitting width?

Slitting accuracy reaches ±0.09 mm with burr levels ≤25 μm, ensuring consistent quality.

Q3: Can the slitting width be customised?

Yes. Width can be adjusted from 20 mm to 280 mm or customised to your required dimensions.

Q4: What control system does it use?

It uses a PLC control unit with an HMI touchscreen for real-time parameter adjustment.

Q5: Is this model suitable for continuous operation?

Yes. It is a roll-to-roll continuous slitting system optimised for long-duration operation in R&D or pilot environments.

Shipping & Return

xReturns Policy

You may return most new, unopened items within 30 days of delivery for a full refund. We'll also pay the return shipping costs if the return is a result of our error (you received an incorrect or defective item, etc.).

You should expect to receive your refund within four weeks of giving your package to the return shipper, however, in many cases you will receive a refund more quickly. This time period includes the transit time for us to receive your return from the shipper (5 to 10 business days), the time it takes us to process your return once we receive it (3 to 5 business days), and the time it takes your bank to process our refund request (5 to 10 business days).

If you need to return an item, simply login to your account, view the order using the "Complete Orders" link under the My Account menu and click the Return Item(s) button. We'll notify you via e-mail of your refund once we've received and processed the returned item.

Shipping

We can ship to virtually any address in the world. Note that there are restrictions on some products, and some products cannot be shipped to international destinations.

When you place an order, we will estimate shipping and delivery dates for you based on the availability of your items and the shipping options you choose. Depending on the shipping provider you choose, shipping date estimates may appear on the shipping quotes page.

Please also note that the shipping rates for many items we sell are weight-based. The weight of any such item can be found on its detail page. To reflect the policies of the shipping companies we use, all weights will be rounded up to the next full pound.

- Choosing a selection results in a full page refresh.