Cell Lab Production Level Attritor Stirred Ball Mill Machine [150L, 300L, 600L]

- £21,659.00

- £21,659.00

- Unit price

- / per

Description

xCell Lab Production Level Attritor Stirred Ball Mill Machine [150L, 300L, 600L]

High-efficiency stirred ball milling for industrial-scale applications

The Cell Lab Production Level Attritor Stirred Ball Mill is engineered for large-scale wet and dry grinding, mixing, and dispersion of materials in industrial environments.

Featuring a high-speed rotating shaft and grinding media agitation mechanism, it achieves rapid particle size reduction through combined impact, shear, and attrition forces.

Designed for continuous or batch processing, this mill is suitable for a broad range of industries, including pharmaceuticals, mining, food, chemicals, metallurgy, and electronics.

Its heavy-duty structure and high-capacity design (150 L to 600 L) make it ideal for pilot-scale and production-scale operations requiring high throughput and long-term stability.

Optional cooling systems ensure consistent thermal management during extended operation, while low vibration and low noise enhance laboratory and plant safety.

Key Features

-

Industrial-scale performance – available in 150 L, 300 L, and 600 L capacities for large-batch or continuous milling operations.

-

Low vibration and noise – reinforced mechanical structure with precision balancing ensures quiet, stable performance.

-

Adjustable speed control – variable-speed operation (60–110 RPM) with optional water-cooling system for thermal stability.

-

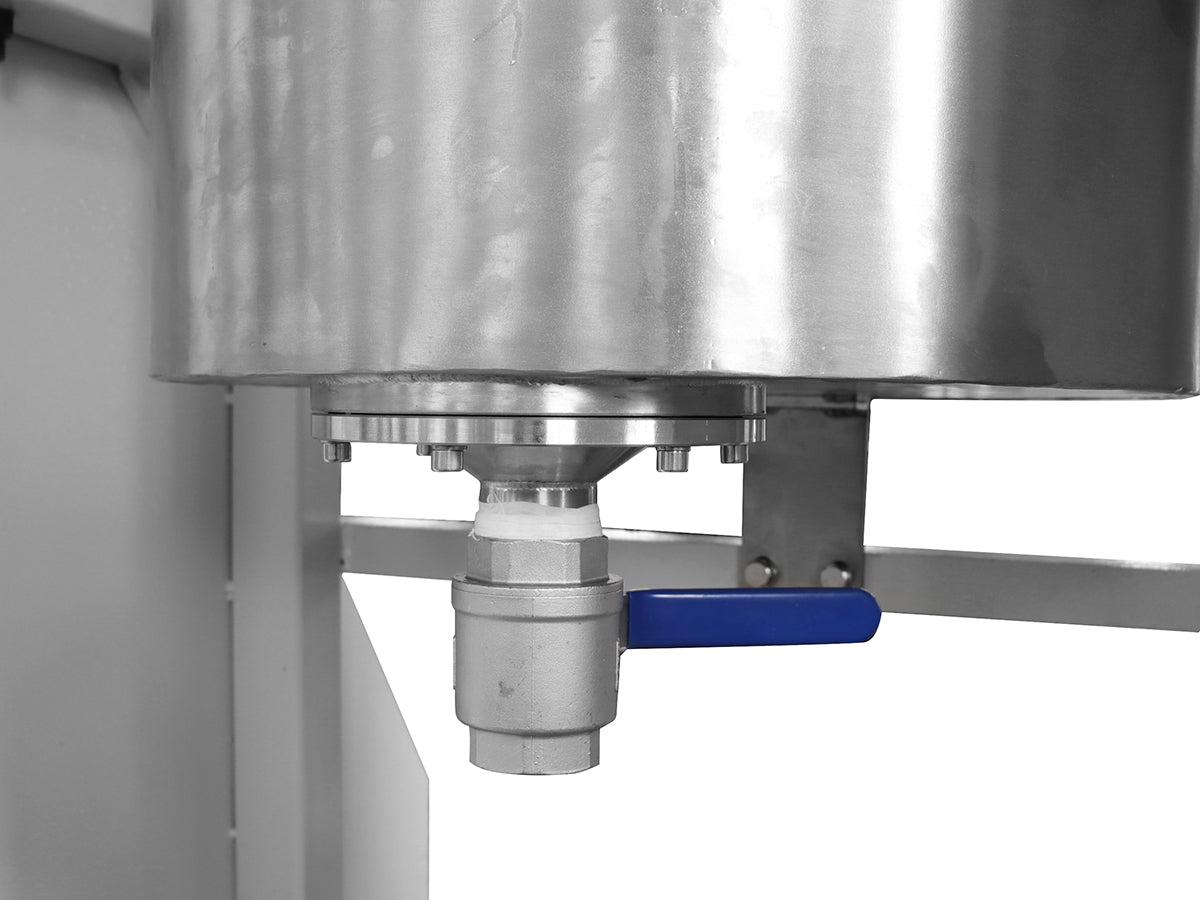

Versatile container materials – compatible with stainless steel, polyurethane (PU), and zirconia chambers for chemical compatibility.

-

Durable and user-friendly design – robust build supports long-term use with minimal maintenance requirements.

Technical Specifications

| Specification | CL0307 | CL0308 | CL0309 |

|---|---|---|---|

| Container Volume (L) | 150 | 300 | 600 |

| Load Volume (L) | 50 | 100 | 200 |

| Rotation Speed (RPM) | 60–110 | 60–110 | 60–110 |

| Sample Feed Size (mm) | ≤ 20 mm | ≤ 20 mm | ≤ 20 mm |

| Voltage | 220V Three-Phase | 220V Three-Phase | 220V Three-Phase |

| Dimension (mm) | 1400 × 960 × 1790 | 1100 × 1000 × 1880 | 2950 × 1500 × 3450 |

| Net Weight (kg) | 790 | 970 | 1930 |

Applications & Industries

Cell Lab production-level attritor mills are widely used for:

-

Battery and energy materials – mixing and dispersion of cathode/anode powders and conductive additives.

-

Ceramic and metallurgical processing – fine grinding of oxides, metals, and composite materials.

-

Pharmaceutical manufacturing – precision homogenisation and particle refinement in formulation processes.

-

Chemical and pigment industries – dispersing coatings, inks, and dyes for consistent viscosity control.

-

Food and nutraceutical sectors – controlled micronisation and suspension mixing for high-purity production.

FAQ

Q1: What distinguishes a stirred ball mill from a planetary ball mill?

A: A stirred ball mill uses continuous media agitation for large-volume, high-efficiency grinding, while planetary mills are used for smaller, higher-energy laboratory-scale milling.

Q2: Can it handle both wet and dry milling?

A: Yes. The system supports both wet and dry processes depending on jar material and sample type.

Q3: What cooling options are available?

A: A circulating water-cooling jacket can be integrated to manage temperature during long-duration or heat-sensitive milling.

Q4: How do I choose between 150 L, 300 L, and 600 L models?

A: Choose based on production capacity: 150 L for pilot lines, 300 L for mid-scale production, and 600 L for full industrial manufacturing.

Q5: What grinding media are recommended?

A: Use stainless steel, zirconia, or alumina beads depending on the material’s hardness and contamination sensitivity.

Shipping & Return

xReturns Policy

You may return most new, unopened items within 30 days of delivery for a full refund. We'll also pay the return shipping costs if the return is a result of our error (you received an incorrect or defective item, etc.).

You should expect to receive your refund within four weeks of giving your package to the return shipper, however, in many cases you will receive a refund more quickly. This time period includes the transit time for us to receive your return from the shipper (5 to 10 business days), the time it takes us to process your return once we receive it (3 to 5 business days), and the time it takes your bank to process our refund request (5 to 10 business days).

If you need to return an item, simply login to your account, view the order using the "Complete Orders" link under the My Account menu and click the Return Item(s) button. We'll notify you via e-mail of your refund once we've received and processed the returned item.

Shipping

We can ship to virtually any address in the world. Note that there are restrictions on some products, and some products cannot be shipped to international destinations.

When you place an order, we will estimate shipping and delivery dates for you based on the availability of your items and the shipping options you choose. Depending on the shipping provider you choose, shipping date estimates may appear on the shipping quotes page.

Please also note that the shipping rates for many items we sell are weight-based. The weight of any such item can be found on its detail page. To reflect the policies of the shipping companies we use, all weights will be rounded up to the next full pound.

- Choosing a selection results in a full page refresh.