![Cell Lab Light Roll Ball Mill [Laboratory Powder Grinding, 30L-2000L]](http://celllab.co.uk/cdn/shop/files/Cell_Lab_Light_Roll_Ball_Mill_Laboratory_Powder_Grinding_30L-2000L_-5_medium.jpg?v=1765732948)

![Cell Lab Light Roll Ball Mill [Laboratory Powder Grinding, 30L-2000L]](http://celllab.co.uk/cdn/shop/files/Cell_Lab_Light_Roll_Ball_Mill_Laboratory_Powder_Grinding_30L-2000L_-6_medium.jpg?v=1765733022)

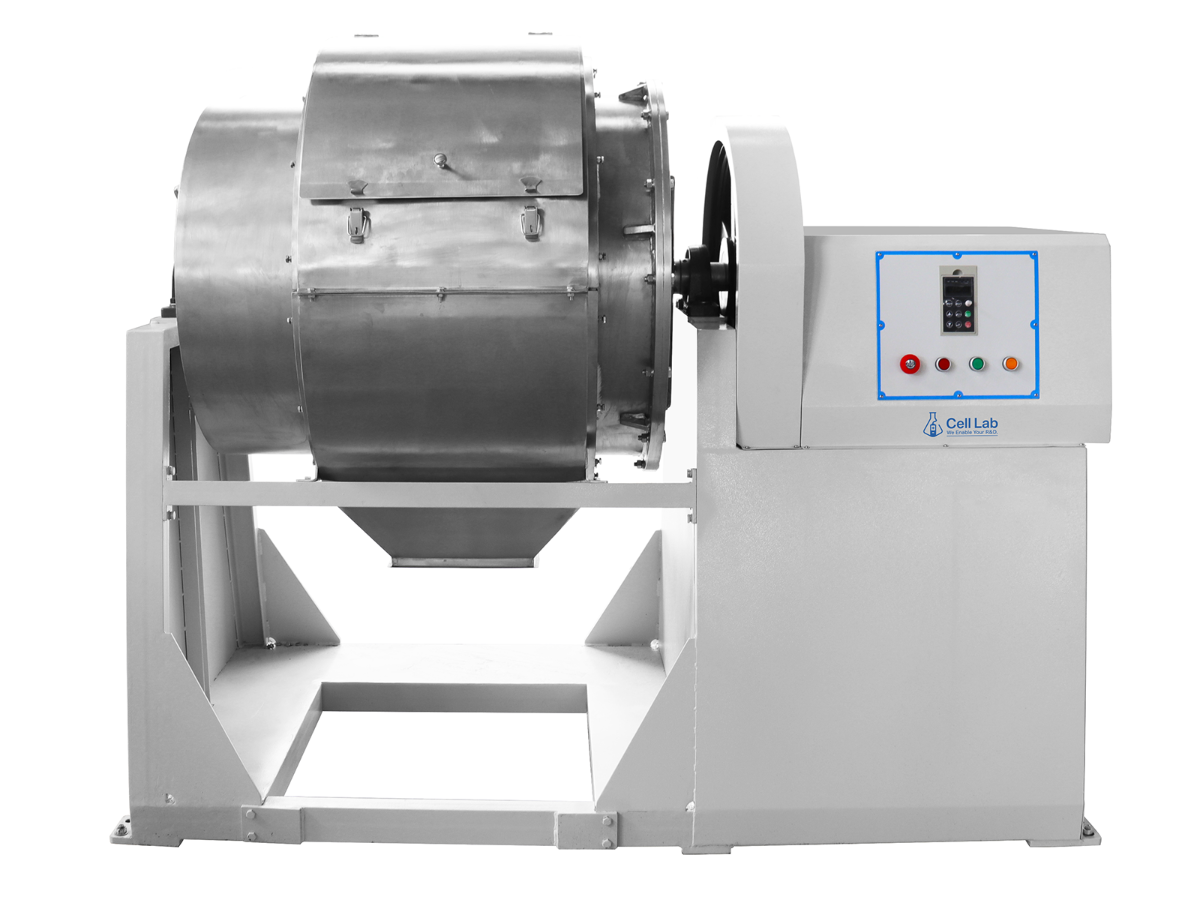

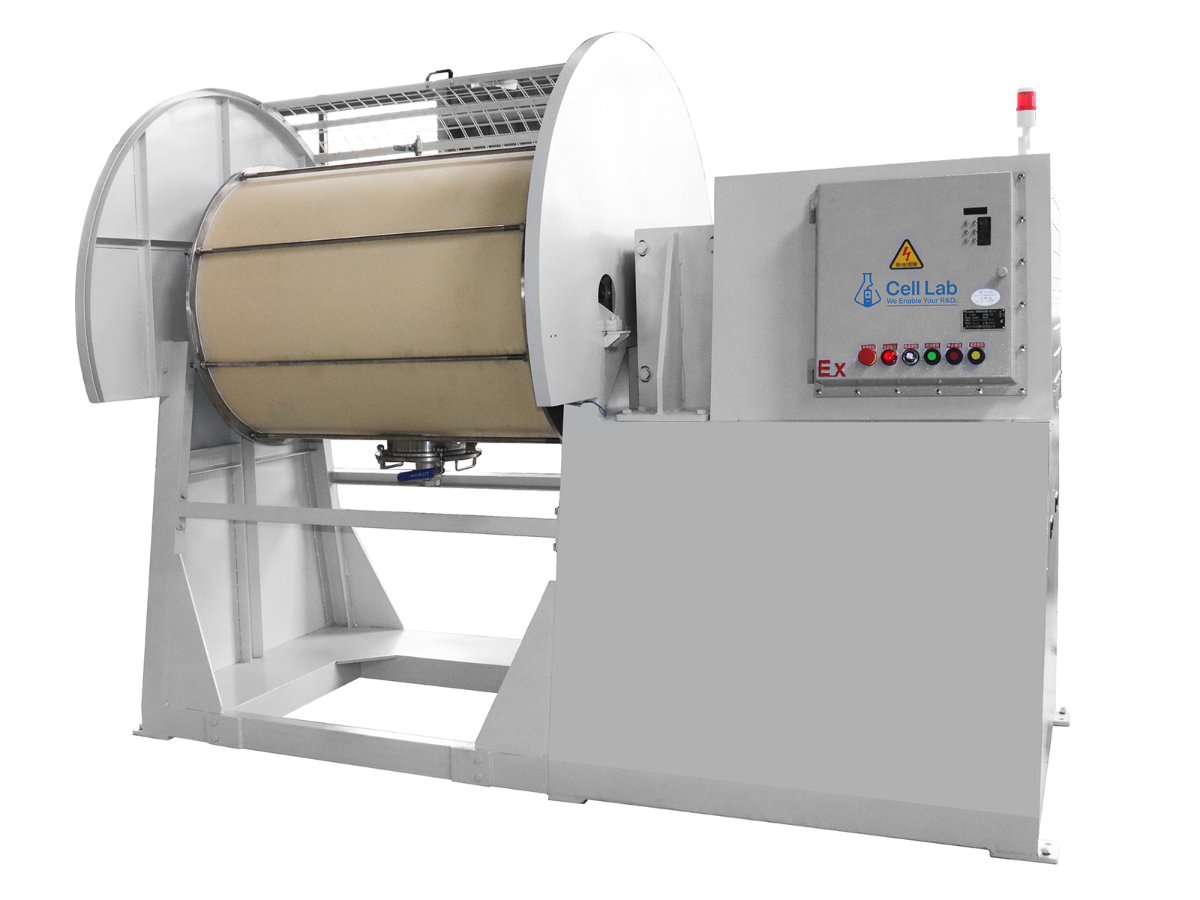

Cell Lab Light Roll Ball Mill [Laboratory Powder Grinding, 30L-2000L]

- £3,649.00

- £3,649.00

- Unit price

- / per

Description

xCell Lab Light Roll Ball Mill [Laboratory Powder Grinding, 30L-2000L]

Compact, efficient and versatile roll ball mill engineered for laboratory-scale micron powder grinding and uniform material mixing.

General Description

The Cell Lab Light Roll Ball Mill is a compact, energy-efficient rolling mill designed for laboratory research and small-batch powder production. With smooth cylinder rotation and multi-mechanism grinding (rolling, cascading, impact and shear), it delivers uniform micron-level powder refinement and reliable material mixing.

It supports both dry and wet milling, making it suitable for electronic materials, ceramic powders, metal powders, magnetic materials, functional materials, minerals, chemicals and advanced materials research. Multiple cylinder and liner materials are available to maintain purity and compatibility with sensitive samples.

The system features adjustable speed, programmable timing, easy media–material separation, and a convenient discharge structure—ideal for laboratories, universities, R&D institutes and pilot-scale production lines requiring consistent, repeatable fine powder preparation.

Key Features

• Compact structure and easy operation – Space-efficient design with smooth rotation and simple maintenance for everyday laboratory use.

• High grinding efficiency and uniform particle size – Rolling motion combined with impact and shear ensures consistent powder fineness for research and small-batch processing.

• Supports dry and wet milling – Flexible for a wide range of materials including metals, ceramics, chemical powders and composite materials.

• Multiple cylinder and liner materials available – Options include carbon steel, stainless steel, nylon, corundum, zirconia, PTFE, and polyurethane for high-purity requirements.

• Convenient discharge and media separation – Designed for fast cleaning, minimal cross-contamination, and efficient sample collection.

Technical Specifications

| Model | Cylinder Volume (L) | Max Capacity (L) | Rotate Speed (rpm) | Power (kW) | Optional Cylinder / Liner Materials | Feed Size (mm) | Output Particle Size (mesh) |

| CL0865 | 30 | 10.5 | 20–60 | 0.75 |

Standard: Stainless Steel Optional: Carbon Steel / Stainless Steel / Nylon / Corundum / Zirconia / PU / PTFE |

≤10 | ≥300 |

| CL0866 | 50 | 17.5 | 20–50 | 1.5 | ≤10 | ||

| CL0867 | 100 | 35 | 20–45 | 2.2 | ≤20 | ||

| CL0868 | 200 | 70 | 20–40 | 4 | ≤20 | ||

| CL0869 | 300 | 105 | 20–38 | 5.5 | ≤20 | ||

| CL0870 | 500 | 175 | 20–36 | 7.5 | ≤20 | ||

| CL0871 | 1000 | 350 | 20–34 | 11 | ≤30 | ||

| CL0872 | 2000 | 700 | 20–34 | 22 | ≤30 |

Applications & Industries

-

Powder grinding and mixing for laboratory research

-

Electronic materials: battery powders, conductive materials, functional composites

-

Ceramic and mineral powder preparation

-

Metal and alloy powder milling

-

Magnetic materials and advanced materials R&D

-

Chemical powders and engineering materials

-

University laboratories, R&D institutes, pilot-scale production lines

(SEO coverage: roll ball mill, laboratory ball mill, powder grinding machine, small-batch milling, micron powder mixing, ceramic powder mill, metal powder milling)

FAQ

Q1: Does the Light Roll Ball Mill support both dry and wet milling?

Yes. It is designed for dry grinding, wet grinding and uniform mixing, depending on material requirements.

Q2: Can it process high-purity or sensitive materials?

Yes. Multiple liner materials—such as zirconia, corundum, PTFE and stainless steel—ensure compatibility with high-purity or chemically sensitive powders.

Q3: What particle size can the machine achieve?

Typical output is ≥300 mesh, suitable for fine powder preparation in materials research.

Q4: Is it suitable for larger-scale batch production?

Yes. The series ranges from 30L to 2000L, enabling both laboratory and pilot-scale production.

Q5: Are the grinding cylinders interchangeable?

Yes. Cylinders and liners can be replaced easily to match different materials and processes.

Shipping & Return

xReturns Policy

You may return most new, unopened items within 30 days of delivery for a full refund. We'll also pay the return shipping costs if the return is a result of our error (you received an incorrect or defective item, etc.).

You should expect to receive your refund within four weeks of giving your package to the return shipper, however, in many cases you will receive a refund more quickly. This time period includes the transit time for us to receive your return from the shipper (5 to 10 business days), the time it takes us to process your return once we receive it (3 to 5 business days), and the time it takes your bank to process our refund request (5 to 10 business days).

If you need to return an item, simply login to your account, view the order using the "Complete Orders" link under the My Account menu and click the Return Item(s) button. We'll notify you via e-mail of your refund once we've received and processed the returned item.

Shipping

We can ship to virtually any address in the world. Note that there are restrictions on some products, and some products cannot be shipped to international destinations.

When you place an order, we will estimate shipping and delivery dates for you based on the availability of your items and the shipping options you choose. Depending on the shipping provider you choose, shipping date estimates may appear on the shipping quotes page.

Please also note that the shipping rates for many items we sell are weight-based. The weight of any such item can be found on its detail page. To reflect the policies of the shipping companies we use, all weights will be rounded up to the next full pound.

- Choosing a selection results in a full page refresh.