- Choosing a selection results in a full page refresh.

Ultra-fine airflow milling for sensitive and high-purity powders

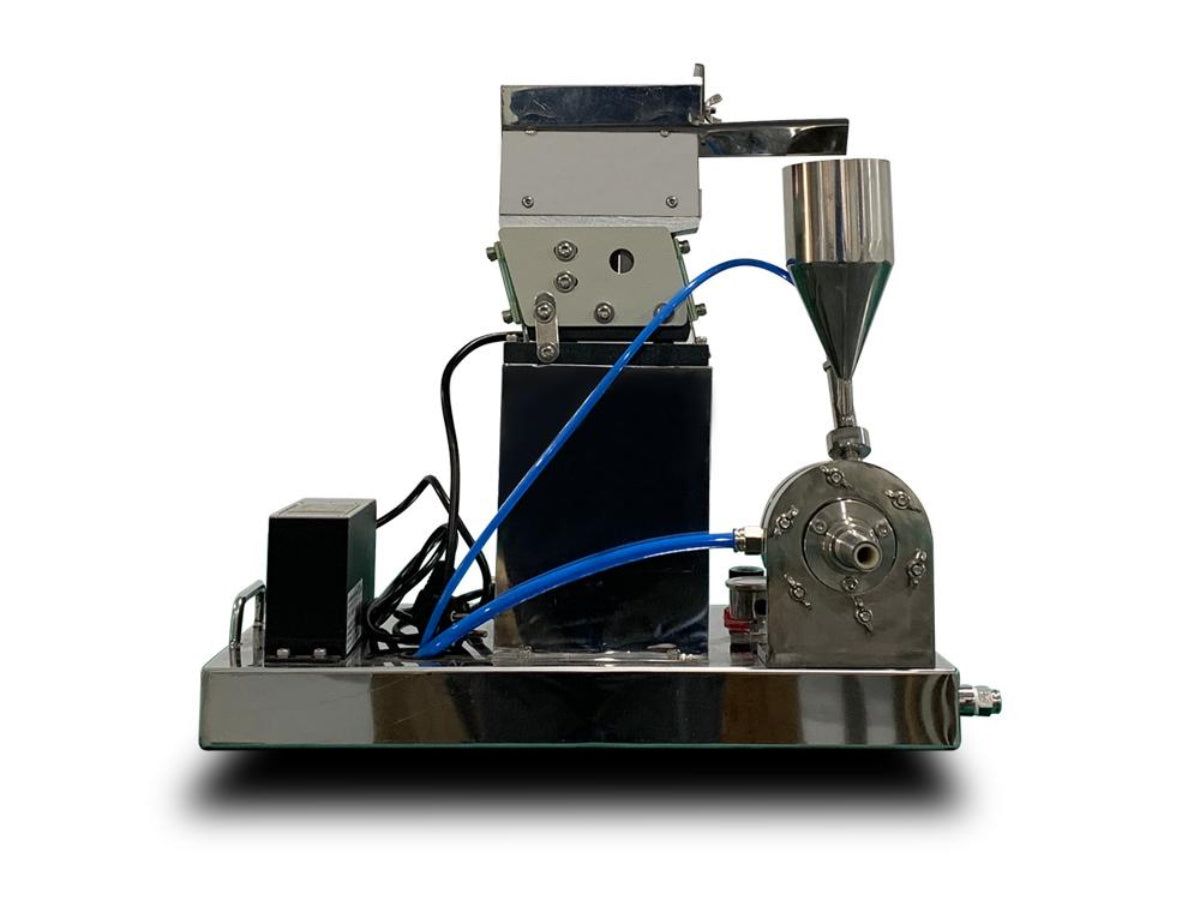

The Cell Lab Laboratory Airflow Pulveriser is a precision engineered system for ultra-fine dry milling of solid-state battery materials, including solid electrolytes, electrode powders, and nanostructured oxides. By operating at low temperatures and avoiding any metal-to-metal contact, it preserves the crystalline integrity and chemical purity of heat-sensitive materials while ensuring uniform particle size distribution and excellent dispersibility.

Ideal for R&D laboratories in energy storage, nanomaterials engineering and advanced functional materials research, this pulveriser supports controlled particle reduction for enhanced ionic conductivity and material reactivity in solid-state battery development.

Efficient Fine Crushing – Generates uniform ultra-fine particles, improving electrode performance and reaction kinetics.

Low Thermal Impact – Maintains low-temperature operation to protect heat-sensitive materials from degradation.

High Purity Operation – Ceramic-lined grinding chamber eliminates metal contamination for high-purity outputs.

Tool-free Cleaning – Quick-clamp connections and smooth interior design enable rapid maintenance and residue-free operation.

Precision Feed Control – Frequency-controlled stainless steel feeder ensures accurate dosage and process repeatability.

Cleanroom Friendly – Fully sealed, dust-free system suitable for use inside glove boxes or controlled lab environments.

|

Item |

Description |

|

Power Supply |

220V, 50Hz |

|

Compressed Air Requirement |

≥1 m³/min at 0.6 MPa (user-supplied) |

|

Feeding System |

Polished stainless steel, 1L volume, frequency-controlled feed |

|

Main Grinding Chamber |

Ceramic-lined interior, 304/316 stainless steel shell |

|

• Supersonic nozzle ring (replaceable) |

|

|

• 4 high-speed nozzles with optimised airflow design |

|

|

• CNC-machined, no rotating parts, fully enclosed |

|

|

Pneumatic Accelerator |

Laval and Venturi nozzles, dead-angle free design |

|

Product Collection Tank |

1L capacity, quick-clamp structure |

|

Control Unit |

Carbon steel cabinet with pressure gauge, reducer, speed control, timer relay, and complete wiring |

|

Air Line Material |

PU tubing with push-in fittings |

|

Machine Dimensions |

304SS: 700 × 500 × 800 mm / 316SS: 700 × 500 × 1000 mm |

|

Net Weight |

304SS: 35 kg / 316SS: 50 kg |

Solid-state battery R&D

Electrolyte and cathode powder processing

Nanomaterials and ceramic oxide synthesis

High-purity phosphor and fluoride materials

Research labs requiring metal-free milling environments

Q1: Can the system operate continuously for long-term experiments?

A1: Yes, its airflow-driven design and non-rotating structure enable continuous, low-wear operation with minimal maintenance.

Q2: Is the machine suitable for handling moisture-sensitive materials?

A2: Yes, it can be integrated into glove boxes or dry rooms for inert-gas operation when processing lithium-based or hygroscopic materials.

Q3: What is the minimum achievable particle size?

A3: Typically below 5 µm, depending on airflow pressure and feed rate parameters.

Q4: Does it require a vacuum or inert gas connection?

A4: No vacuum is needed; it operates purely by compressed airflow, but nitrogen can be used as an inert gas option if required.

Q5: What materials are recommended for the ceramic liner?

A5: Alumina and zirconia liners are available to match specific hardness and purity requirements.

You may return most new, unopened items within 30 days of delivery for a full refund. We'll also pay the return shipping costs if the return is a result of our error (you received an incorrect or defective item, etc.).

You should expect to receive your refund within four weeks of giving your package to the return shipper, however, in many cases you will receive a refund more quickly. This time period includes the transit time for us to receive your return from the shipper (5 to 10 business days), the time it takes us to process your return once we receive it (3 to 5 business days), and the time it takes your bank to process our refund request (5 to 10 business days).

If you need to return an item, simply login to your account, view the order using the "Complete Orders" link under the My Account menu and click the Return Item(s) button. We'll notify you via e-mail of your refund once we've received and processed the returned item.

We can ship to virtually any address in the world. Note that there are restrictions on some products, and some products cannot be shipped to international destinations.

When you place an order, we will estimate shipping and delivery dates for you based on the availability of your items and the shipping options you choose. Depending on the shipping provider you choose, shipping date estimates may appear on the shipping quotes page.

Please also note that the shipping rates for many items we sell are weight-based. The weight of any such item can be found on its detail page. To reflect the policies of the shipping companies we use, all weights will be rounded up to the next full pound.

Thanks for subscribing!

This email has been registered!