- Choosing a selection results in a full page refresh.

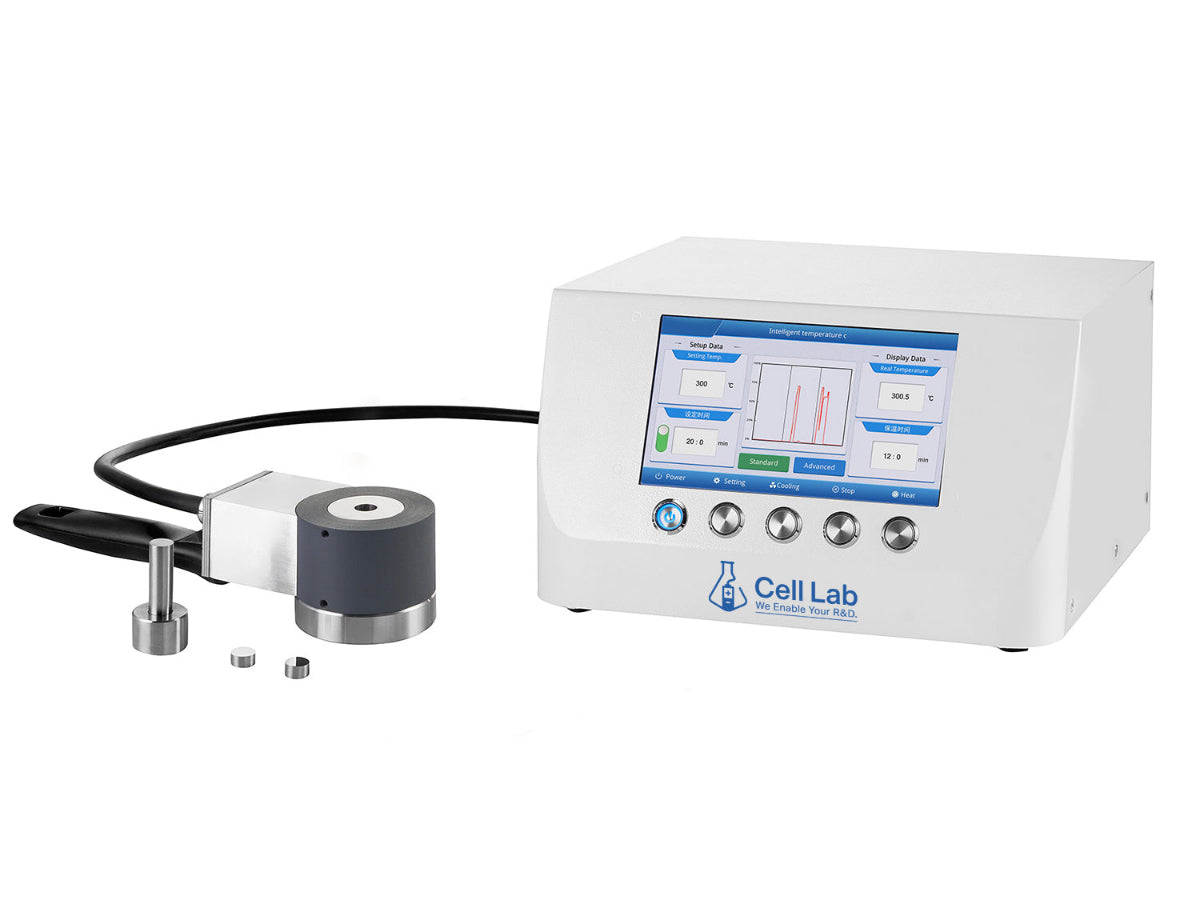

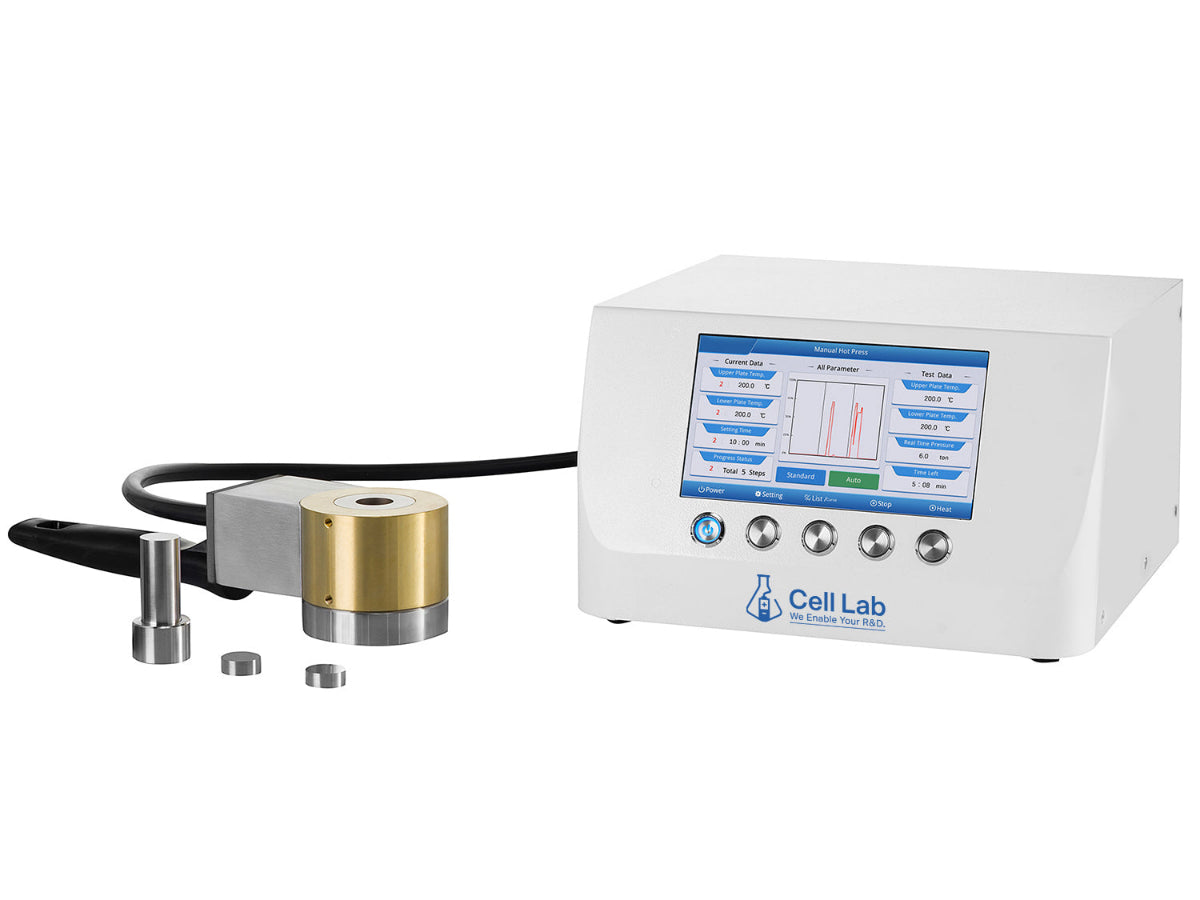

Precision Heated Pellet Dies for Laboratory Powder Compaction

The Cell Lab Heating Pellet Pressing Die Set series is engineered for compressing powders into cylindrical pellets under controlled temperature conditions. Made from hardened alloy steel (AISI D2, equivalent to JIS SKD11 / GB Cr12MoV / DIN 1.2379), these dies provide high hardness (Rc 60–62) and durability for laboratory applications.

Available in diameters from 0.25" (6.35 mm) to 1" (25.4 mm), with heating ranges up to 300 °C or 500 °C, the die sets are ideal for temperature-sensitive powders such as polymers, resins, and materials prone to phase transition. They are also widely used in battery R&D, ceramics, minerals, and pharmaceuticals.

Optional cooling stages are available at additional cost. Other diameters and geometries can be customised upon request.

Multiple sizes – Available in 0.25", 0.4", 0.5", and 1" diameters.

Heating capability – Models support heating up to 300 °C or 500 °C, with rates of 5–10 °C/min.

High hardness alloy steel – Constructed from AISI D2 / SKD11 tool steel for durability and wear resistance.

Temperature-sensitive material testing – Suitable for polymers, resins, and phase-transition powders.

Customisable options – Cooling stage and special die geometries available upon request.

| Product No. | Core Diameter | Heating Range | Core Depth | Dimensions (L × H) | Max Pressing Force (RT) | Max Pressing Force (Heated) | Recommended Pressure | Max Pressure | Power Supply |

|---|---|---|---|---|---|---|---|---|---|

| CL0677 | 0.25" (6.35 mm) | 0–300 °C | 45 mm | 78 × 138 mm | 2T | 1T | ≤800 MPa | 1200 MPa | 220V / 50 Hz, 300W |

| CL0678 | 0.4" (10 mm) | 0–300 °C | 45 mm | 78 × 138 mm | 6T | 3T | ≤800 MPa | 1200 MPa | 220V / 50 Hz, 300W |

| CL0679 | 0.5" (12.7 mm) | 0–300 °C | 45 mm | 78 × 138 mm | 10T | 5T | ≤800 MPa | 1200 MPa | 220V / 50 Hz |

| CL0680 | 1" (25.4 mm) | 0–300 °C | 45 mm | 90 × 138 mm | 39T | 19T | ≤800 MPa | 1200 MPa | 220V / 50 Hz |

| CL0681 | 0.4" (10 mm) | 0–500 °C | 45 mm | 78 × 138 mm | 6T | 3T | ≤800 MPa | 1200 MPa | 220V / 50 Hz |

| CL0682 | 0.25" (6.35 mm) | 0–500 °C | 45 mm | 78 × 138 mm | 2T | 1T | ≤800 MPa | 1200 MPa | 220V / 50 Hz |

| CL0683 | 0.5" (12.7 mm) | 0–500 °C | 45 mm | 78 × 138 mm | 10T | 5T | ≤800 MPa | 1200 MPa | 220V / 50 Hz |

| CL0686 | 1" (25.4 mm) | 0–500 °C | 45 mm | 90 × 138 mm | 39T | 19T | ≤800 MPa | 1200 MPa | 220V / 50 Hz |

Material: Hardened alloy steel (AISI D2 tool steel, equivalent to JIS SKD11, GB Cr12MoV, DIN 1.2379).

Rockwell Hardness: Rc 60–62.

Set Includes: Pressing die, heating unit, and temperature controller.

Battery R&D – Electrode material pellet pressing.

Ceramics & minerals – Compaction of ceramic powders and geological samples.

Pharmaceuticals – Laboratory-scale drug formulation studies.

Polymer & resin research – Heated pressing of phase-sensitive materials.

Material science – Preparation of pellets for spectroscopy and analysis.

Q1: What sizes are available?

A: Standard diameters include 0.25", 0.4", 0.5", and 1". Custom sizes can be manufactured upon request.

Q2: What is the maximum heating capability?

A: Models are available with either 300 °C or 500 °C heating range.

Q3: Can these dies handle fine powders below 50 microns?

A: It is not recommended to press powders smaller than 50–100 microns, as they may slip into die gaps and damage the sleeve.

Q4: Is a cooling stage included?

A: No. Cooling stages are optional and can be purchased separately.

Q5: Are pressing dies covered under warranty?

A: Pressing dies are consumables; only manufacturing defects are covered. Damage from misuse, rust, or fine particle intrusion is excluded.

You may return most new, unopened items within 30 days of delivery for a full refund. We'll also pay the return shipping costs if the return is a result of our error (you received an incorrect or defective item, etc.).

You should expect to receive your refund within four weeks of giving your package to the return shipper, however, in many cases you will receive a refund more quickly. This time period includes the transit time for us to receive your return from the shipper (5 to 10 business days), the time it takes us to process your return once we receive it (3 to 5 business days), and the time it takes your bank to process our refund request (5 to 10 business days).

If you need to return an item, simply login to your account, view the order using the "Complete Orders" link under the My Account menu and click the Return Item(s) button. We'll notify you via e-mail of your refund once we've received and processed the returned item.

We can ship to virtually any address in the world. Note that there are restrictions on some products, and some products cannot be shipped to international destinations.

When you place an order, we will estimate shipping and delivery dates for you based on the availability of your items and the shipping options you choose. Depending on the shipping provider you choose, shipping date estimates may appear on the shipping quotes page.

Please also note that the shipping rates for many items we sell are weight-based. The weight of any such item can be found on its detail page. To reflect the policies of the shipping companies we use, all weights will be rounded up to the next full pound.

Thanks for subscribing!

This email has been registered!