- Choosing a selection results in a full page refresh.

High-efficiency vacuum mixing and defoaming for viscous, powder, and slurry-based materials

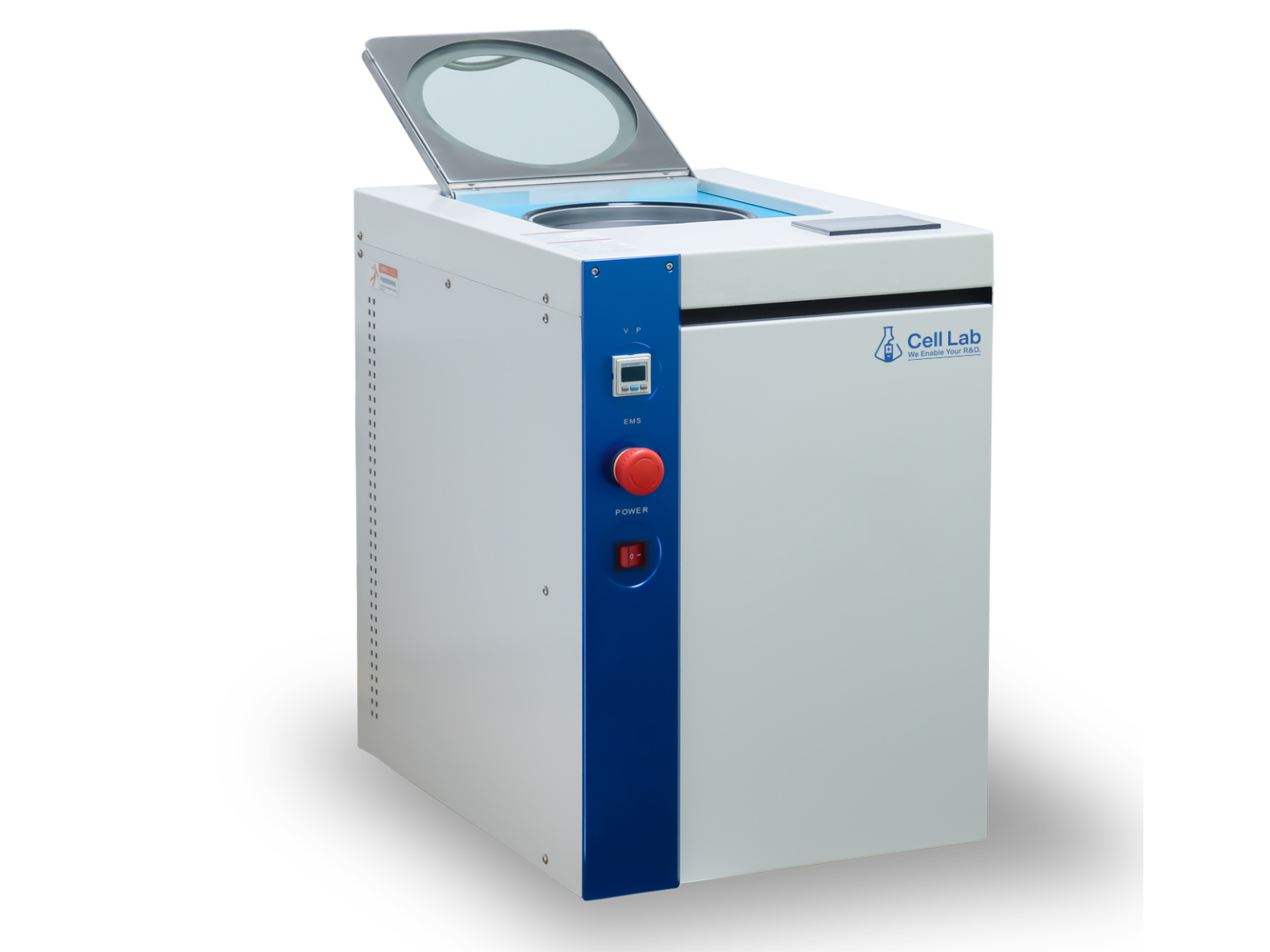

The Cell Lab™ Dual-Container Planetary Vacuum Mixer combines planetary centrifugal motion with vacuum integration to deliver uniform, bubble-free mixing of viscous or composite materials. Designed for battery slurry, conductive paste, ceramic, polymer, and nano-material processing, this system ensures excellent dispersion, repeatability, and purity.

Equipped with dual 300 ml mixing containers, a 750 W high-torque motor, and a closed-loop PLC touchscreen control, it provides precise programmable operation, automatic balancing, and built-in safety interlocks—ideal for both R&D laboratories and small-scale production requiring consistent, contamination-free performance.

• Dual-Container Planetary Motion System

Synchronised rotation and revolution (fixed ratio 0.6) create powerful three-dimensional shear forces for thorough blending of powders, liquids, and pastes.

• Integrated Vacuum Defoaming Control

Vacuum level adjustable up to –98 kPa with 0.1 kPa accuracy eliminates air bubbles and moisture during mixing, enhancing uniformity and film integrity.

• Intelligent Programmable Interface

Dual closed-loop PLC with 7-inch touchscreen supports up to 6 custom parameter sets and 3-segment operation cycles for repeatable, high-precision processing.

• Robust Safety and Stability Design

Automatic lid lock, imbalance detection, and overload protection ensure safe operation during high-speed rotation (up to 2000 rpm).

• High-Efficiency Drive System

Equipped with a 750 W high-torque motor and precision gear transmission, delivering smooth, vibration-free performance and long service life.

| Model | CL0028 (Dual Container) |

|---|---|

| Standard Mixing Cups | 2 × 300 ml (Φ77 × H85 mm) |

| Optional Cup Sizes | 10 ml / 30 ml / 50 ml / 100 ml (on request) |

| Max Load Capacity | 2 × 300 g |

| Mixing Principle | Planetary centrifugal (rotation:revolution = 0.6 fixed) |

| Speed Control | Stepless, 300–2000 rpm, 1 rpm precision |

| Revolution Ratio | 0.6 × rotation speed |

| Max Speed | 2000 rpm |

| Motor Drive | High-torque 750W motor |

| Vacuum Pumping Rate | 165 L/min |

| Vacuum Pressure | -98 KPa (adjustable; 0.1 KPa accuracy; with delay) |

| Program Memory | Up to 6 parameter sets |

| Balancing Method | Dual-sided counterweight tuning |

| Operation Timing | 0–600s, divided into 3 segments (up to 200s each) |

| Control System | Dual closed-loop PLC with touchscreen interface |

| Lubrication System | Sealed sleeve design, splash protection, passive lube |

| Protection & Alerts | Imbalance / Lid open / Motor overload |

| Safety Features | Automatic shutdown, lid auto-lock during operation |

| Drive Transmission | Precision gear-driven |

| Power Supply | AC 220V, 50Hz |

| Total Power Consumption | 1.35 KW |

| Unit Dimensions (W×H×D) | 400 × 590 × 580 mm (not including handle/external parts) |

| Machine Net Weight | 92 kg |

Lithium-ion and solid-state battery electrode slurry preparation

Conductive paste, ceramic, and metal powder blending

Adhesives, inks, and polymer composites mixing

Nano-powder dispersion and resin homogenisation

Research & pilot-scale manufacturing in energy materials, electronics, and chemistry

Q1: What advantages does vacuum mixing provide over traditional mixing?

A1: It removes entrapped air and moisture, improving material density, consistency, and electrical conductivity in battery and conductive pastes.

Q2: Can this mixer handle both powders and liquids simultaneously?

A2: Yes. The planetary centrifugal mechanism ensures homogeneous dispersion for both solid–liquid and liquid–liquid systems.

Q3: Is it suitable for high-viscosity materials like silicone or epoxy?

A3: Absolutely. The 750 W motor and gear drive deliver sufficient torque for high-viscosity paste processing.

Q4: How many operation programs can be saved?

A4: Up to six customised recipes can be stored and recalled directly from the PLC interface.

Q5: What maintenance is required?

A5: Routine inspection of seals, cup gaskets, and vacuum lines is recommended. The enclosed lubrication system requires no daily maintenance.

You may return most new, unopened items within 30 days of delivery for a full refund. We'll also pay the return shipping costs if the return is a result of our error (you received an incorrect or defective item, etc.).

You should expect to receive your refund within four weeks of giving your package to the return shipper, however, in many cases you will receive a refund more quickly. This time period includes the transit time for us to receive your return from the shipper (5 to 10 business days), the time it takes us to process your return once we receive it (3 to 5 business days), and the time it takes your bank to process our refund request (5 to 10 business days).

If you need to return an item, simply login to your account, view the order using the "Complete Orders" link under the My Account menu and click the Return Item(s) button. We'll notify you via e-mail of your refund once we've received and processed the returned item.

We can ship to virtually any address in the world. Note that there are restrictions on some products, and some products cannot be shipped to international destinations.

When you place an order, we will estimate shipping and delivery dates for you based on the availability of your items and the shipping options you choose. Depending on the shipping provider you choose, shipping date estimates may appear on the shipping quotes page.

Please also note that the shipping rates for many items we sell are weight-based. The weight of any such item can be found on its detail page. To reflect the policies of the shipping companies we use, all weights will be rounded up to the next full pound.

Thanks for subscribing!

This email has been registered!