Cell Lab Automatic Precision Vacuum Drying Oven [Pluggable Shelf Heating | PID Touch Control | Optional Pump Integration]

- £2,749.00

- £2,749.00

- Unit price

- / per

Description

xCell Lab Automatic Precision Vacuum Drying Oven [Pluggable Shelf Heating | PID Touch Control | Optional Pump Integration]

Advanced programmable vacuum drying system for heat-sensitive and oxygen-intolerant materials

The Cell Lab™ Automatic Precision Vacuum Drying Oven provides intelligent, fully automated vacuum drying performance for temperature-sensitive, easily oxidised, or decomposable materials. With independent shelf heating, automatic vacuum regulation, and touchscreen PID control, it is designed for high-precision drying, degassing, and heat treatment in pharmaceutical, chemical, food, and environmental laboratories.

B-type models include a built-in high-efficiency vacuum pump with dual filtration system for plug-and-play operation and long service life.

Key Features

• Independent Shelf Heating System

Each aluminium shelf is directly and independently heated, ensuring accurate temperature uniformity across all layers. Ideal for differential drying and multi-sample precision processing.

• Fully Automatic Vacuum Regulation

Set the desired vacuum level — the system adjusts automatically with dual exhaust modes (manual and electric). Standard air intake port and 10 mm nozzle support controlled gas exchange and nitrogen purging.

• Smart PID Touchscreen Control

Equipped with a 7.0-inch LCD colour touchscreen, supporting multi-step temperature and vacuum programming (up to 30 steps), real-time curve tracking, parameter memory, and USB data export.

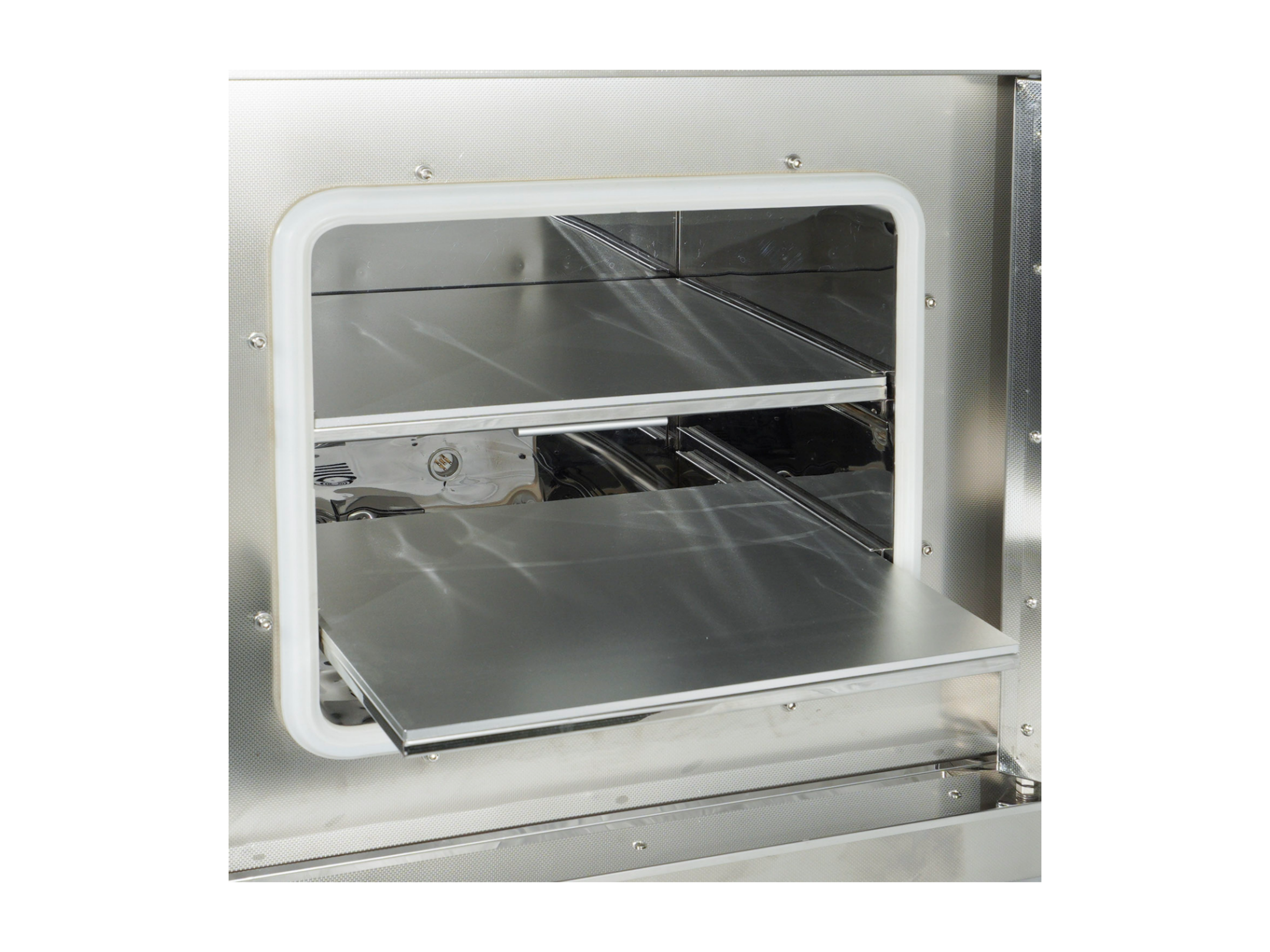

• Durable SUS304 Stainless-Steel Chamber

The chamber and shelves are constructed from SUS304 stainless steel and 5083 corrosion-resistant aluminium, surrounded by aluminium silicate insulation for maximum thermal stability and operator safety.

• Integrated Vacuum Pump & Dual Filtration (B-type)

Models with “B” suffix include a two-stage rotary vane vacuum pump (2 L/s – 16 L/s) and dual filter system — inlet drying filter and exhaust oil mist filter — for clean, low-maintenance performance.

Technical Parameters:

|

Model |

DO0037A |

DO0038A |

DO0039A |

||||

|

DO0037B |

DO0038B |

DO0039B |

|||||

|

Heating mode |

Shelf direct heating |

||||||

|

Function |

Temp. Range |

RT+10-250℃ |

|||||

|

Vacuum degree Range |

<133Pa |

||||||

|

Temp. Resolution Ratio |

0.1℃ |

||||||

|

Temp. motion |

±1℃ |

||||||

|

Heating-up time |

≤40minutes |

||||||

|

Structure |

Inner Chamber |

SUS304 mirror stainless steel |

|||||

|

Outer Shell |

SUS304 embossed stainless steel |

||||||

|

shelf |

5083 Corrosion resistant aluminum plate |

||||||

|

Insulation Layer |

Aluminium silicate fibre |

||||||

|

Heater |

Mica electrothermal film |

||||||

|

Observation window |

Bulletproof tempered glass |

||||||

|

Vacuum meter |

Absolute pressure accuracy class 0.25 |

||||||

|

Exhaust device |

Manualand electric double exhaust device |

||||||

|

Air intake port |

Standard inflation port |

||||||

|

BLT Vacuum Pump System (BL:without Vacuum Pump ) |

Double stage rotary vane vacuum pump 2LS |

Double stage rotary vane vacuum pump 4L/S |

Double stage rotary vane vacuum pump 16L/S |

||||

|

Vacuum pump air inlet drying fiter |

|||||||

|

Vacuum pump exhaust oil mist filter |

|||||||

|

Nozzle Diameter |

10mm |

||||||

|

Power rating |

A:1.2kW |

A:1.6Kw |

A: 2.5kW |

||||

|

Controller |

Temp. control mode |

7.0-inch LCD color touch screen multi-stage PID program temperature control, single shelf independent temperature control |

|||||

|

Temp. setting mode |

Touch Screen Type |

||||||

|

Timer |

0-9999 minutes/ 0-9999 hours (can adjust) |

||||||

|

Operation function |

Fixed value operation, regular operation, automatic stop |

||||||

|

Fixed Value Mode |

Control temperature and vacuum at the same time |

||||||

|

Program Mode |

Control temperature and control vacuum at the same time 30 programmable operation |

||||||

|

Additional function |

Real-time temperature curve recording. with U disk data storage and export function |

||||||

|

Vacuum pump oil return preventer |

|||||||

|

Sensor deviation correction, temperature overshoot self-setting, internal parameter locking, power off parameter memory |

|||||||

|

Temp.Sensor |

PT100 |

||||||

|

Safety device |

Over temperature sound-light alarm, mechanical temperature limiter, sensor fault alarm, over vacuum degree alarm |

||||||

|

Specification |

Inner Chamber size(W*L*H)(mm) |

415*370*340 |

450*450*450 |

550*600*650 |

|||

|

Exterior size (W*L*H)(mm) |

A type:635*565*796 |

A type: 670*645*906 |

A type: 770*795*650 |

||||

|

Packing size (W*L*H)(mm) |

A type:804*705*957 |

A type:840*785*1062 |

A type:940*935*1262 |

||||

|

Volume |

52L |

91L |

214.5L |

||||

|

Number of shelf |

2 |

||||||

|

Load per rack |

15kg |

||||||

|

Shelf space |

140mm |

185mm |

265mm |

||||

|

Current rating (50/60HZ) |

AC220V |

AC220V |

AC220V |

||||

|

NW/GW (kg) |

A: 67/92 |

A: 82/105 |

A:180/210 |

||||

|

Accessory |

Shelf |

2 |

|||||

|

Shelf frame |

4 |

||||||

|

Optional Accessories |

Shelf( Independent temperature control ), RS485 Transfer to USB Communication Interface, Printer, WIFI control module |

||||||

Applications & Industries

-

Drying and degassing of pharmaceutical ingredients

-

Thermal treatment of chemicals and polymers

-

Dehydration of food, biological, and plant samples

-

Vacuum packaging and environmental testing

-

Research and pilot-scale production requiring oxygen-free drying

FAQ

Q1: What’s the key difference between A-type and B-type models?

A1: A-type models require an external vacuum pump. B-type models include a built-in two-stage rotary vane pump with dual filtration, ready for immediate operation.

Q2: How is temperature controlled for each shelf?

A2: Each shelf has independent PID-controlled heating, allowing uniform temperature distribution and programmable multi-step operation.

Q3: What’s the vacuum control precision?

A3: The oven maintains <133 Pa with automatic regulation and dual exhaust control for consistent low-pressure environments.

Q4: Can the system record and export drying data?

A4: Yes — the touchscreen controller records real-time temperature and vacuum curves, exportable via USB.

Q5: What safety features are included?

A5: The unit features multi-layer safety protection, including over-temperature, over-vacuum, sensor failure alarms, and power-off recovery.

Shipping & Return

xReturns Policy

You may return most new, unopened items within 30 days of delivery for a full refund. We'll also pay the return shipping costs if the return is a result of our error (you received an incorrect or defective item, etc.).

You should expect to receive your refund within four weeks of giving your package to the return shipper, however, in many cases you will receive a refund more quickly. This time period includes the transit time for us to receive your return from the shipper (5 to 10 business days), the time it takes us to process your return once we receive it (3 to 5 business days), and the time it takes your bank to process our refund request (5 to 10 business days).

If you need to return an item, simply login to your account, view the order using the "Complete Orders" link under the My Account menu and click the Return Item(s) button. We'll notify you via e-mail of your refund once we've received and processed the returned item.

Shipping

We can ship to virtually any address in the world. Note that there are restrictions on some products, and some products cannot be shipped to international destinations.

When you place an order, we will estimate shipping and delivery dates for you based on the availability of your items and the shipping options you choose. Depending on the shipping provider you choose, shipping date estimates may appear on the shipping quotes page.

Please also note that the shipping rates for many items we sell are weight-based. The weight of any such item can be found on its detail page. To reflect the policies of the shipping companies we use, all weights will be rounded up to the next full pound.

- Choosing a selection results in a full page refresh.