- Choosing a selection results in a full page refresh.

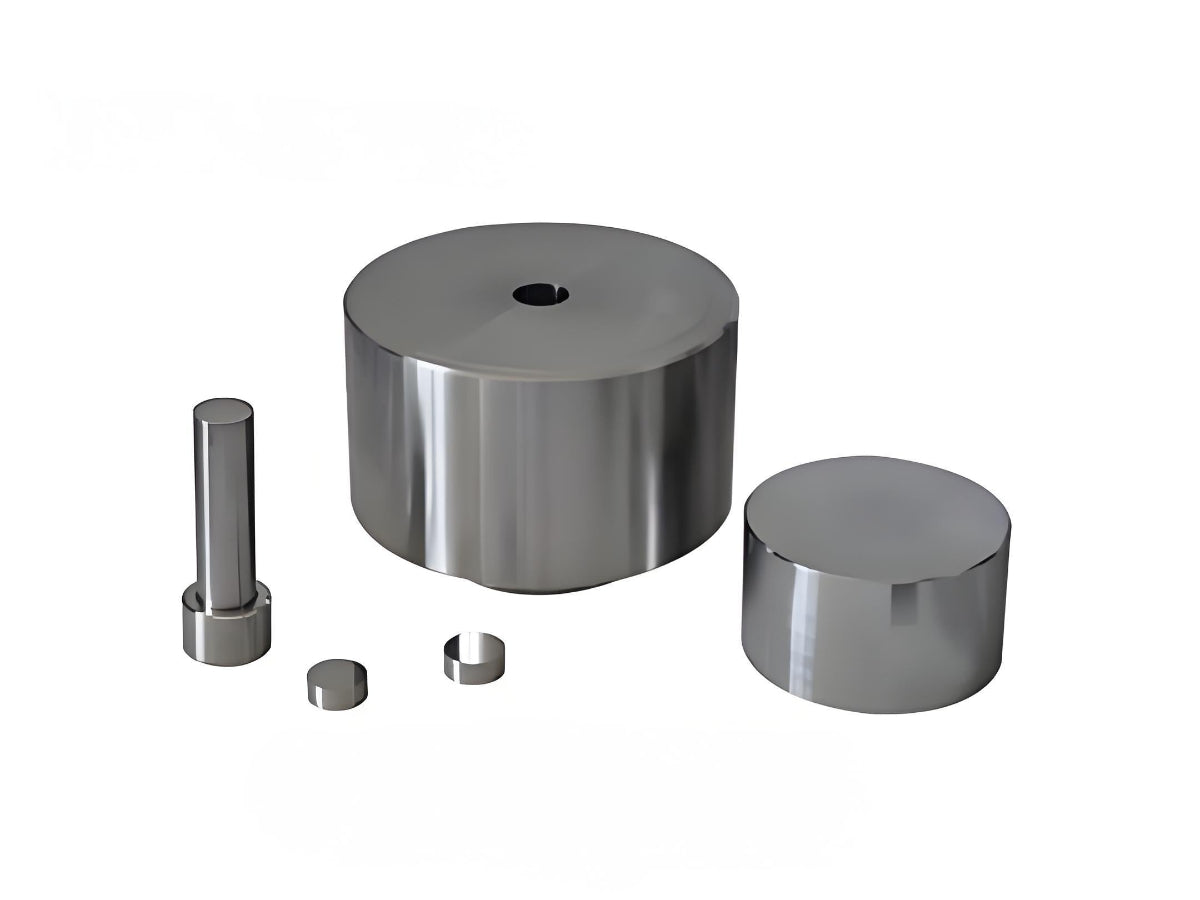

Specially designed die sets to reduce pellet cracking during powder compaction

Cell Lab Anti-cracking Pressing Die Sets are engineered to minimise the risk of cracking in pressed pellets, providing researchers and manufacturers with higher reliability in sample preparation. Constructed from Cr12MoV alloy tool steel with indenter hardness of HRC60–62, these dies are suitable for both laboratory and industrial use.

Available in 5 mm, 10 mm, and 40 mm diameters, the series supports a wide range of applications in pharmaceuticals, materials science, analytical chemistry, and powder metallurgy. Their specialised design ensures uniform pressure distribution and enhanced pellet integrity, making them ideal for fragile or brittle powder systems such as halide salts and ceramic powders.

Anti-cracking design — Minimises pellet fracture during demolding and handling.

Durable tool steel construction — Made from Cr12MoV alloy steel, hardened to HRC60–62.

Multiple cavity sizes — Available in 5 mm, 10 mm, and 40 mm formats.

Laboratory & industrial use — Suitable for spectroscopy, powder metallurgy, and analytical testing.

Customisable options — Additional sizes and split-type designs available upon request.

| Product No. | Reference Sample Size | Cavity Depth (mm) | Die Material | Indenter Hardness | Dimensions (mm) | Weight |

|---|---|---|---|---|---|---|

| CL0623 | Φ5 mm (0.2") | 40 | Cr12MoV Alloy Tool Steel | HRC60–62 | Φ98 × 120 | 5.0 kg |

| CL0624 | Φ10 mm (0.4") | 40 | Cr12MoV Alloy Tool Steel | HRC60–62 | Φ98 × 120 | 5.0 kg |

| CL0625 | Φ40 mm | 40 | Cr12MoV Alloy Tool Steel | HRC60–62 | Φ100 × 120 | 8.0 kg |

Infrared spectroscopy (FTIR, KBr pellets) — Reliable pellet preparation without cracks.

Ceramics & brittle materials — Ideal for compacting fragile powders into dense pellets.

Pharmaceuticals — Tablet pressing and powder compaction for uniformity testing.

Analytical chemistry — Sample preparation for spectroscopy and material analysis.

Powder metallurgy — Pressing metallic and composite powders with reduced failure rate.

Q1: How does the anti-cracking design work?

It applies optimised pressure distribution to reduce stress concentration, minimising pellet breakage.

Q2: Which materials benefit most from these dies?

Fragile powders such as KBr, halide salts, ceramics, and brittle compounds.

Q3: Can these dies be used with high pressures?

Yes. They are designed for standard laboratory press loads, but avoid exceeding manufacturer recommendations.

Q4: How should the dies be maintained?

Clean and dry after each use; lightly oil the surface if storing for long periods to prevent rust.

Q5: Are custom cavity sizes available?

Yes. Cell Lab offers custom anti-cracking pressing dies on request.

You may return most new, unopened items within 30 days of delivery for a full refund. We'll also pay the return shipping costs if the return is a result of our error (you received an incorrect or defective item, etc.).

You should expect to receive your refund within four weeks of giving your package to the return shipper, however, in many cases you will receive a refund more quickly. This time period includes the transit time for us to receive your return from the shipper (5 to 10 business days), the time it takes us to process your return once we receive it (3 to 5 business days), and the time it takes your bank to process our refund request (5 to 10 business days).

If you need to return an item, simply login to your account, view the order using the "Complete Orders" link under the My Account menu and click the Return Item(s) button. We'll notify you via e-mail of your refund once we've received and processed the returned item.

We can ship to virtually any address in the world. Note that there are restrictions on some products, and some products cannot be shipped to international destinations.

When you place an order, we will estimate shipping and delivery dates for you based on the availability of your items and the shipping options you choose. Depending on the shipping provider you choose, shipping date estimates may appear on the shipping quotes page.

Please also note that the shipping rates for many items we sell are weight-based. The weight of any such item can be found on its detail page. To reflect the policies of the shipping companies we use, all weights will be rounded up to the next full pound.

Thanks for subscribing!

This email has been registered!